PROFESSIONAL TIPS

Food Processing

The California Raisin industry offers a variety of products that are suitable for both consumer and industrial usage. The vast majority of the products offered are of the “Vitis vinifera” Natural Seedless varietal type and are typically dried by the sun, whether it is on paper trays or dried on the vine. Natural (Sun-Dried) seedless raisins include the Thompson seedless and other newer cultivars such as Selma Pete, Fiesta and DOVine. California Golden Seedless and California Dipped Seedless raisins are mechanically dried and processed. Other raisin varietal types include Zante Currant, Muscat, Monnuka, Sultana, and other Seedless. Raisins may also be further processed into Raisin Paste and Raisin Juice Concentrate.

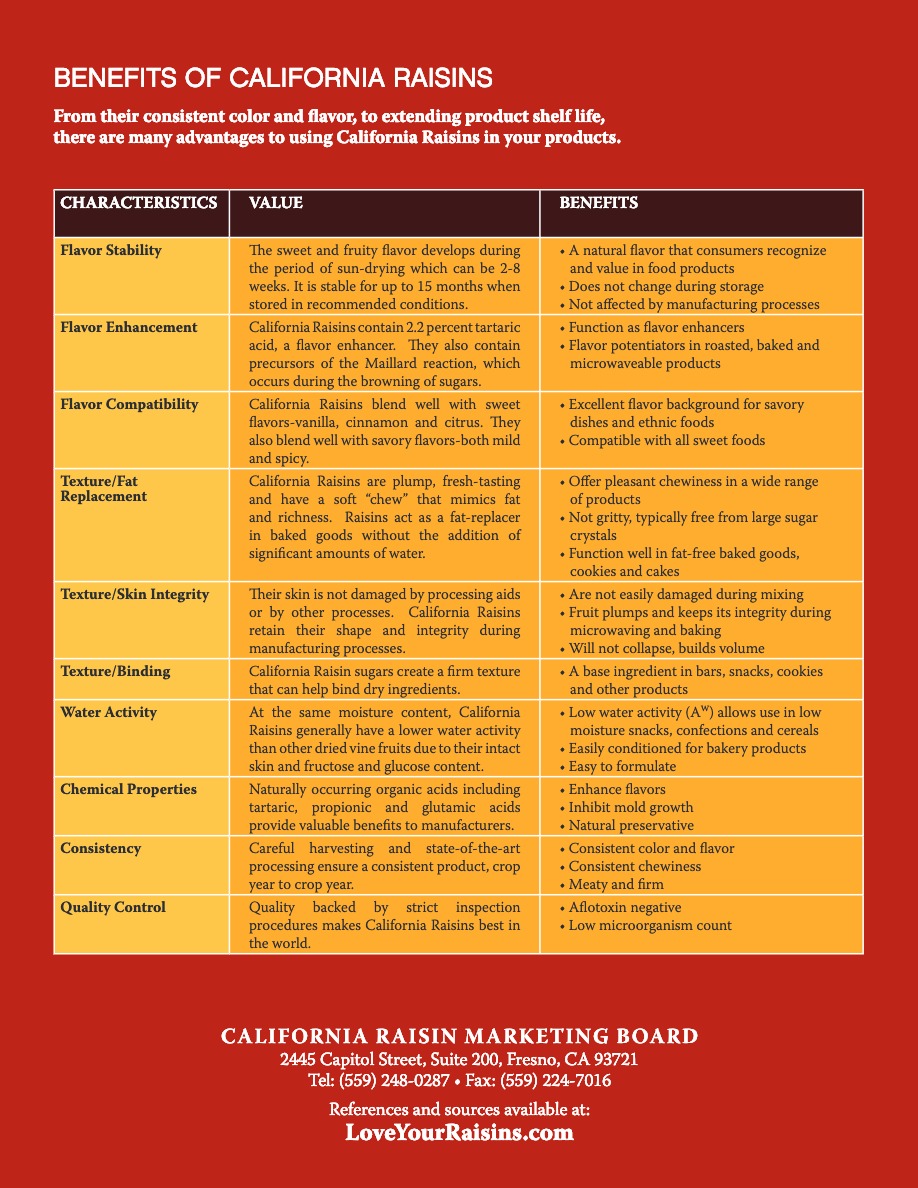

California Raisins provide flavor, texture, and color to a wide variety of products. Their natural sweetness allows for reductions of the sugar levels in formulations, and their high water binding capacity helps to retain moisture in bakery products. Based on their numerous attributes, raisins are adaptable to a variety of other manufactured products appealing to the new and growing market for health conscious consumers.

FOOD PROCESSING

Technical Brochure

In the California Raisins brochure, you will find a listing of all raisins products and their applications, characteristics, availability and storage, and composition information.

California Raisins provide flavor, texture, and color to a wide variety of products. Their natural sweetness allows for reductions of the sugar levels in formulations, and their high water binding capacity helps to retain moisture in bakery products. Based on their numerous attributes, raisins are adaptable to a variety of other manufactured products appealing to the new and growing market for health conscious consumers.

Click here for References & Sources for California Raisin Technical Brochure.

FOOD PROCESSING

Conditioning Raisins

In the Conditioning raisins is an important step in the production of raisin breads. If raisins are not conditioned but added directly to the dough, they will draw moisture from the bread during fermentation and baking. This also causes the bread to stale during shipping and distribution, which reduces the shelf life.

Raisins can be used right out of the case, but experienced bakers commonly condition raisins in advance. This involves re-hydrating raisins to the desired moisture level.

For small quantities, the American Society of Bakery Engineers recommends that quantities of not more than 30 lbs be conditioned by adding 12 to 15 percent of warm water by weight to the raisins right in the case. Temperature of the water should not exceed 75° to 80°F and 3.6 to 4.5 lbs of water to 30 lbs of raisins. Re-close the poly-liner, cover the container, and turn it a number of times to distribute the water uniformly. Turn again after about 2 hours and allow to stand for an additional 2 hours for a total conditioning time of at least 4 hours or overnight. Longer periods may over condition and release more solids from the raisins. Any remaining liquid should be added to the dough as part of the liquid component in the formula. Do not condition raisins in excessively hot water. For best results, raisins should be about 75°F at the end of the process.

For larger quantities, the American Institute of Baking recommends that raisins be placed in a trough or tank with a screened bottom opening for draining the water. Completely cover the raisins with water at 75° to 80°F and then, drain. Close the drain to retain leached solids and cover the trough or tank and allow the raisins to absorb the surface water for at least 4 hours or overnight. Longer periods may over condition and release more solids from the raisins. Any remaining liquid should be added to the dough as part of the liquid component in the formula. Do not condition raisins in excessively hot water. For best results, raisins should be about 75°F at the end of the process.

FOOD PROCESSING

Processing Details

The processing of California raisins involves a multi-faceted process, including inspection by the USDA to ensure the raisins meet federal standards. Part of the crop is selected to make raisin juice and raisin paste for commercial applications. Before raisins are unloaded, government inspectors gather samples from the middle of each box to make sure they are free of imperfections. Then they’re “processed”, size-graded, washed in pure water and moved through a laser sorter to remove any unwanted material.

After final inspections, raisins are automatically weighed and packed in a variety of convenient sizes and shipped around North America and the world.

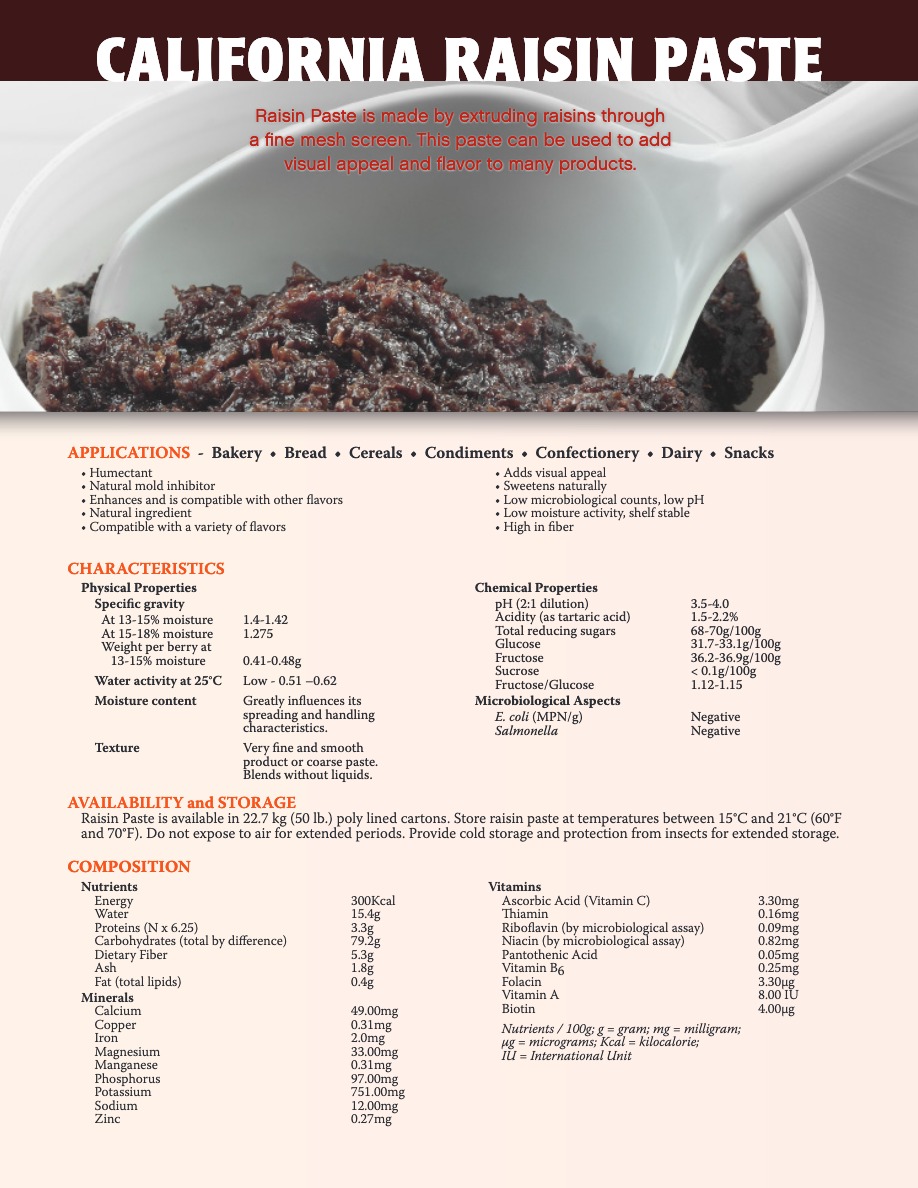

Part of the crop is used to make raisin juice (a minimum of 70 percent natural fruit soluble solids) and raisin paste (made from 100 percent raisins), which are added to a variety of foods, including dairy, confectionery and bakery items.

The production and manufacturing of California Raisins for consumption is a fascinating process. Understanding all the aspects of raisins, the products made from them, benefits of their use, and the differences as they are manufactured – all that information resides in the technical brochure.

FOOD PROCESSING

Storage

Temperature

California Raisins may be stored at room temperature without noticeable loss of color or flavor for a few months. Raisins should be stored away from grain products such as wheat flour and corn meal.

Storage & Handling Tips:

To maintain optimum freshness, keep raisins sealed in an airtight container in your coolest storage area.

Raisins freeze well for long periods of time. They also thaw quickly at room temperature for a quick, convenient and healthy snack.

When raisins become dry or when a recipe calls for plumped raisins, cover the amount needed with very hot tap water and soak for 2 to 5 minutes. (Do not soak any longer than five minutes. Flavor and important nutrients can be lost.)

When chopping raisins, always use a lightly oiled knife or blade.

FOOD PROCESSING

Quality Assurance

The Finest From California

It’s August in the San Joaquin Valley. Another bountiful season is coming to a close. Trucks are taking loads of raisins from the farmers’ yards to the packing plants – a mark of the season’s end.

Before raisins are unloaded from their bins, government inspectors take long prods to gather samples from the middle of each box. United States Department of Agriculture (USDA) standards must be met to ensure that each box is free of imperfections. Next, raisins are processed, which means they go through a series of conveyor belts and drums to remove remaining stems, chaff or lightweight fruit. The raisins also are sent through a vacuum air stream to catch any other undesirable materials. Finally, they’re size-graded and thoroughly washed in pure water. In preparation for packaging, the raisins are moved through a laser sorter. The sorter’s light beams, along with a computer, see if anything besides raisins is passing through the stream. If material other than a raisin is present, the computer sends a burst of air to knock it out of the stream of raisins and down a trough. California raisins are inspected under the most rigid standards. Quality control technicians inspect the raisins by hand throughout the packing process, thus assuring that California raisins are the cleanest, highest quality in the world. After final inspections, raisins are automatically weighed and packed in a variety of convenient sizes. California raisins are then shipped around North America and the world for consumers to enjoy.

Purchasing Specifics:

Parent Grape: Seedless

Description: Naturally sun-dried.

Approximately 2000-2400 berries/kg (1000-1200 berries/lb.)

Packaging: Available in 12.5 kg cases, 11.3, 13.6 and 18.1 kg containers (25, 30 and 40 lbs.)

Availability: Excellent supply year-round.

FOOD PROCESSING

FAQs

California Raisins have a moisture content of around 18 percent. Most of the performance bars on the market today also have a moisture content in this range. So the transfer will be minimal either from the raisin to the bar or bar to raisin.

California Raisins have a very mild flavor and tend to pick up other spices and flavors in formulas and impart desirable flavors of their own. This synergy between the raisin and other flavors in the bar may have created this chocolate sensation.

Tea biscuit manufacturers in England and in the USA tend to utilize small or mini small raisins or Zante currants. At one time there was a diced raisin available, but I do not think it is offered anymore except by special order. Typically raisins are diced right out of the case in a commercial food processor. I have never seen this done on large scale operations but this is how it is done in small bakeries.

Some bakers like the idea of crushed raisins in a product to give sweetness and color. But you definitely will see a darkness of the product. Most of the moisture transfer will occur right in the mixing and the remaining product will have a high percentage of raisin skin, which has a lower moisture than the interior of the raisin. This should not add extra problems to the product in small batch goods. For commercial operations, this is an untested area.

Small raisins, mini small raisins, and Zante currants are the choices of biscuit makers.

Remember a few years ago when all of the rage in the bakery world was to include plum or prune paste and lower the fat? Well, if you read into the old editions of the Raisin Report from the ’80s you will see that this was a concept pioneered by the California Raisin Advisory Board. Simply put: the addition of raisin paste gives the product a texture and feel to the mouth that emulates fat. Formulators can reduce or eliminate fat with the inclusion of raisin paste. The concept was used by cookie manufacturers across the USA. From my perspective, raisin paste is superior in the fat replacement area over plum or prune paste from a formulation standpoint: 1. Raisin paste has a mild flavor which blends right into the product without a strong fruit flavor. (and) 2. Plum paste is more acidic and can sometimes affect the yeast in a product.

Substitute on a pound for pound basis. You can add non-fat dry milk if dough is too watery or add water if the dough is too stiff.

High fructose and moisture content helps maintain shelf life. (We do not have controlled experiments to prove superiority over other shortenings, but we guess it is as good or better.) We have an upcoming project in this area.

There are two different products available to the food industry which may work in this product category: 1. Drum dried raisins. Natural raisins are dried to around four percent moisture and powdered. 2. Spray dried or crystallized raisin juice concentrate. This is a powdered version of raisin juice concentrate. Due to the fact that raisins are so hygroscopic, there is normally an anticaking agent added to the product.

We monitor new product introductions monthly, and we see more and more raisin usage in high quality and gourmet specialty products. For example, there is a demand for savory sauces, Middle Eastern foods and other products sweetened and enhanced with raisins.

A real area of potential is our neighbor in the South – Mexico. Although they do produce raisins in the state of Sonora, they have a rising high quality baking industry in the major cities including Mexico City and Monterrey. Some of these same bakery industries have U.S. operations and even own some of the largest bakeries in the USA. And, they are moving to raising product standards on the Mexican market as well. California Raisins fit right into this need.

There are so many places in the world with raisin consuming traditions that are so eager to try California Raisins. In Russia, for example, there are more than 100 different types of breads produced at a typical bakery. Most traditionally have contained raisins. India has a long tradition of raisin usage and produces only a small amount. They use raisins in dishes from chutneys to dosas.

From a taste and appearance standpoint, no. Some will say they are sweeter and taste different but I cannot tell the difference.

The term “natural” has not been defined in FDA’s law (the Federal Food, Drug, and Cosmetic Act) or in FDA’s regulations. Of course, the word has a meaning to most consumers, and in the absence of an official definition, the common or usual meaning prevails for regulatory purposes. To many consumers, the term “all natural” would mean that a food is made without chemical food additives or refined ingredients. The Food Safety and Inspection Service, USDA which regulates meat and poultry products, has established policies on the use of claims on food labels, including natural and organic claims.

No. The labeling act of 1990 is very specific in what we can say about food products. We recommend that a manufacturer check any wording and claim with a labeling or packing attorney. You can also research these questions at https://www.ams.usda.gov/nop/ USDA Organic Standards.

The California raisin is laid on clean paper or plastic trays in the sunshine right in the rows of the vineyards. They stay in this state until they reach a moisture content of around 15 percent. At this time, they are what we call field grade raisins. This means they are dry and quite hard and have a firm skin. Right after harvesting, the field grade raisins are “blown out” to remove any field materials. Then they are placed in wooden bins until they are ready to be processed. Because of the hard dry nature of the field grade raisin, it is possible to rigorously wash the raisin to remove dirt, sand or foreign materials. Visual and mechanical high tech inspections remove any materials or substandard raisins from the process.

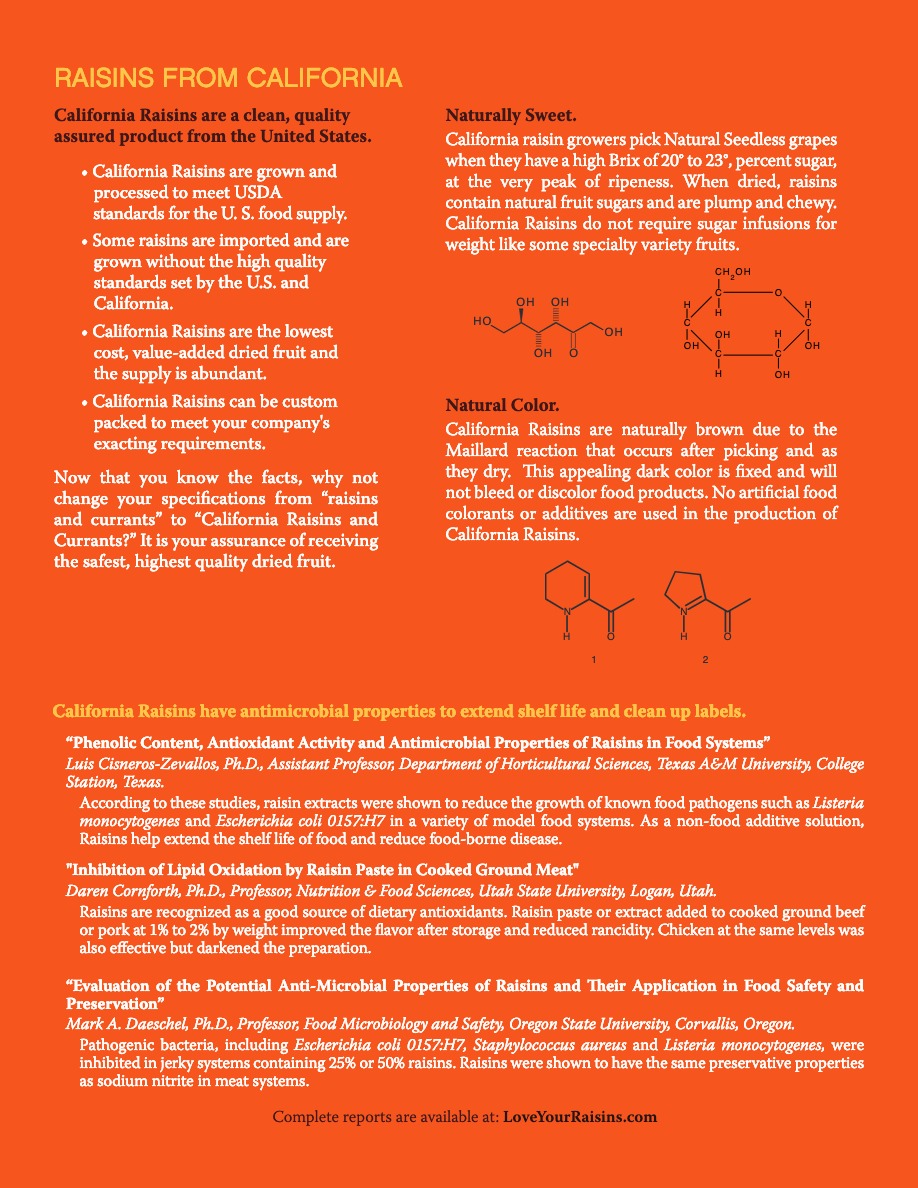

Raisins contain a naturally occurring organic acid called propionic acid. This substance serves as a natural mold inhibitor and has been proven to decrease mold growth in bakery products. This is especially interesting in flat breads like pitas, tortillas and others which naturally have high moisture contents and are susceptible to mold.

1000-2000 raisins/lb (2,000-2,400/kg)

25, 27.5 and 30 lb containers (11.3, 12.5 and 13.6 kg)

At 25° C, water activity is 0.51-0.56 at 13-15% moisture and 0.55-0.62 at 15-18% moisture.

CALIFORNIA RAISINS

Social Media

Find us on our social media network.